Rotary Pouch Filling & Sealing M/C

Rotary pouch machine is for readymade pouches.

-

Various pouch types are available : doypack, zipper doypack, flat bag. corner spout pouch

-

Changeover time < 5 min (through product recipe function on HMI)

-

Applications : powder, granule, liquid, paste, etc.

-

Model : 1 up & 2 up

-

Models according to the bag gripping size and required speed.

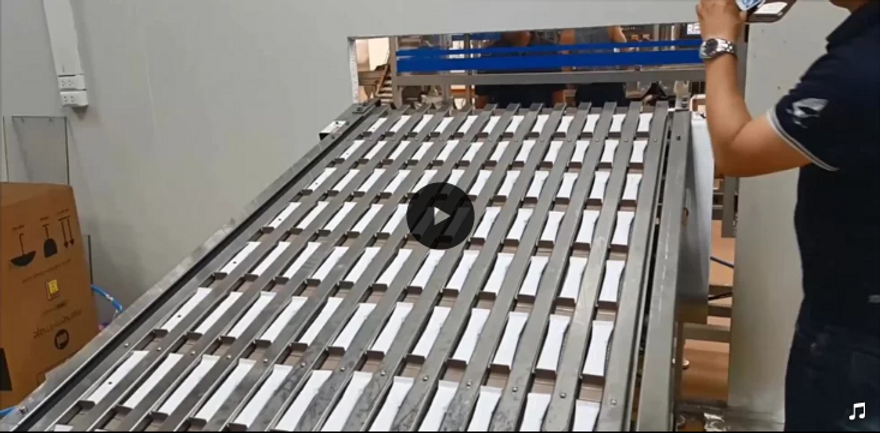

Rotary pouch machine & mask feeding system / 1up model

-

Speed is 60 bags per min with the best speed compared to the normal rotary pouch machine

-

Compact size

-

Piston filler actuated by servo control

-

Easy changeover manually to change bag gripping size about for 5 ~ 10 minutes

-

Reasonable price

-

Option : Patches feeding & counting system

Rotary pouch machine for liquid and paste / 2 up model

-

High speed model : 60~80 bags /min

-

Bag gripping ranges(mm) / 80~120, 90~150, 90~165, 140~200

-

Product recipe / 10 items / gripping size, operation speed, sealing temperature, filling volume

-

Piston filler actuated by servo control / option : heating jacket for hot fill

-

Easy changeover through product recipe, 2 minutes

-

Washdown design / IP65

-

Date coder / Inkjet printer, embossing coder

-

Option : Patches feeding & counting system

Rotary pouch machine for dried product / 2 up model for zipper pouch

-

Speed is 60 ~70 bags per min with the best speed compared to the normal rotary pouch machine

-

Bag gripping ranges(mm) / 80~120, 90~150, 90~165, 140~200

-

Stations / 6, 8

-

Product recipe / 10 items / gripping size, operation speed, sealing temperature

-

Pouches types / Premade doypack, zipper doypack, flat bag

-

Filling system / Auger filler, multihead weigher, cup feeder

-

Easy changeover manually to change bag gripping size about for 5 ~ 10 minutes

-

Less footprint

-

Option / check weigher, date coder, metal detector, delta robot

Rotary pouch machine & IQF pancake / 1up model

-

Speed is 30~50 bags per min with the best speed compared to the normal rotary pouch machine

-

Bag gripping range : 100~250mm, 145~320mm, 160~350mm

-

Stations / 6, 8, 10

-

Product recipe / 10 items / gripping size, operation speed, sealing temperature

-

Special counting and feeding system for IQF pancake

-

Easy changeover manually to change bag gripping size about for 5 ~ 10 minutes

Rotary pouch machine for fully opened side gusset bag / 1up model

-

M type pouches

-

Speed / Max.35 bags per min

-

Applications / Coffee sticks, powder, granules, pet food

-

Stations / 7

-

Mechanical bag gripping / bag gripping range 90mm~210mm

-

Easy changeover manually to change bag gripping size about for 5 ~ 10 minutes

-

Stick counting conveyor, date coder, check weigher